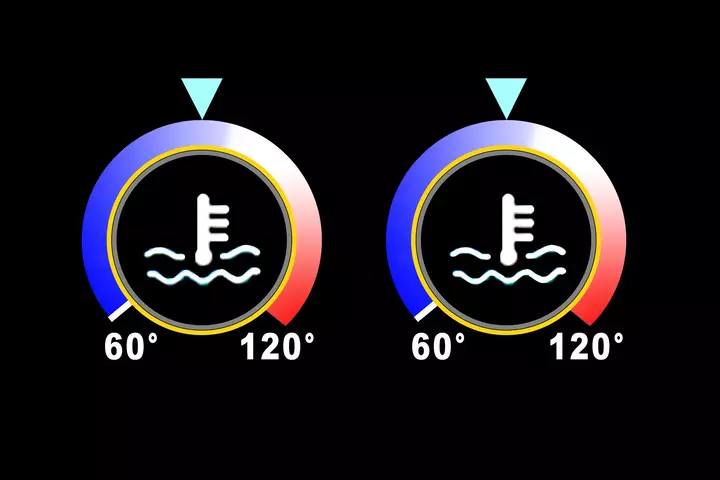

Hydraulically pilot-controlled travel pedals

- The hydraulically pilot-controlled travel pedals provide comfortable and precise control without mechanical wear. Driving with foot control leaves the hands free for other functions. This saves time and increases operating comfort.